Classification: Sulphenamides Accelerator

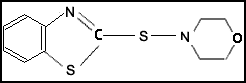

Chemical Structure:

Chemical name: N-Oxydiethylene-2-Benzothiazole Sulfenamide

Molecular formula: C11H12N2S2O

CAS No.: 102-77-2

Specification:

| Index Name | Index | |

| Appearance | - | Pale yellow |

| Physical Form | - | Granule |

| Initial melting point | ℃, min | 78.0 |

| Loss on heating | %, max | 0.40 |

| Ash content | %, max | 0.30 |

| N.W.per bag | kg | 25 |

Properties: Light yellow or orange crystal (granule). No poison with a little odor of ammonia. The density is 1.34-1.40. Soluble in benzene, acetone, chloroform. Insoluble in water acid and alkali with lower concentration.

Application: NOBS is an excellent delayed action type accelerator. Can be used in NR, IR, BR, SBR and NBR and EPDM. superior to CBS and TBBS in stability and delayed vulcanization under severe conditions. Recommended in place of CBS in difficult processing conditions. Recommended to be used in combination with small amount of Guanidines. Gives excellent and mechanical properties to rubber products. Offer extended scorch safety for large size extrusion products, rubber compounds with high loading of furnace black such as ISAF and SAF,injection or transfer molded products.

Storage: To keep the bags tightly closed in a cool, well-ventilated place at 25℃ max, to place the goods on the dry wooden shelf at a height of 20cm min. And to avoid from moisture, sunshine, light and fires. The recommended max.shelf life is six months.

Package: 25kg paper bag or PP weaved bag lined with plastic bag.