Classification: Thiazoles Accelerator

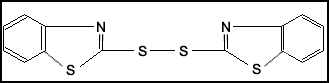

Chemical Structure:

Chemical name: 2,2`-Dithiobisbenzothiazole Disulfide

Molecular formula: C14H8N2S4

CAS No.: 120-78-5

Specification:

| Index Name | Index | |||

| Appearance | Gray white or light yellow | |||

| Physical Form | - | Powder | Oil Powder | Granule |

| Initial Melting Point | ℃, min | 166.0 | 166.0 | 166.0 |

| Loss on Heating | %, max | 0.40 | 0.40 | 0.40 |

| Ash Content | %, max | 0.30 | 0.30 | 0.30 |

| Residue on Sieve (150um) | %, max | 0.10 | 0.10 | / |

| Oil Content | % | / | 1-2 | / |

| N.W.Per Bag | kg | 20/25 | 20/25 | 20/25 |

Properties: Light yellow powder or granule with a little osmyl and taste bitter. The density is 1.42-1.52. Soluble is ethyl acetate, ethanol, solution of NaOH and Na2CO3. Insoluble in benzene, water and gasoline.

Application: MBTS can be used as fast accelerator in NR, IR, BR, SBR, NBR and EPDM. Secondary accelerators are usually required for synthetic rubbers. Having critical curing temperature higher than MBT, MBTS can prevent premature curing and scorching. During the first stage of vulcanization, it gives a long delayed action and keeps the rubber compound soft for a long period of time. This is the most characteristic feature of MBTS. When such a delayed action is required, it is recommended to use in combination with basic accelerators such as TMTD and DPG for safe processing. Can be used in almost all types of rubber products except those in contact with food, as the rubber products after vulcanization develop bitter taste.

Storage: To keep the bags tightly closed in a cool, well-ventilated place at 25℃ max, to place the goods on the dry wooden shelf at a height of 20cm min. And to avoid from moisture, sunshine, light and fires. The recommended max.shelf life is two years.

Package:20/25kg paper bag or PP weaved bag lined with plastic bag.